1GB Equals How Much MB And How Long Can It Be Used For?

Discover how many MB is 1GB and understand the data consumption for various activities to optimize your internet usage.

Thermal glue plays an important role in helping to cool the heatsink so that the CPU has more contact with the heatsink and conducts heat better. Join WebTech360 to learn more about thermal paste as well as the types of glue available on the market today.

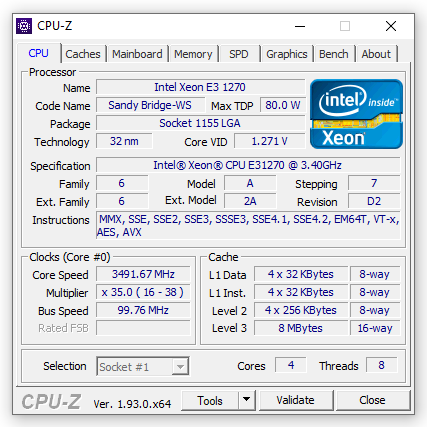

Thermal paste (thermal paste or thermal grease and there are dozens of names such as: thermal gel, thermal compound, but in general, Thermal Interface Material - TIM) is an almost indispensable thing on every laptop. computers from desktop to laptop. It is a form of heat conductor, slightly liquid or glue-like, so it is called thermal paste.

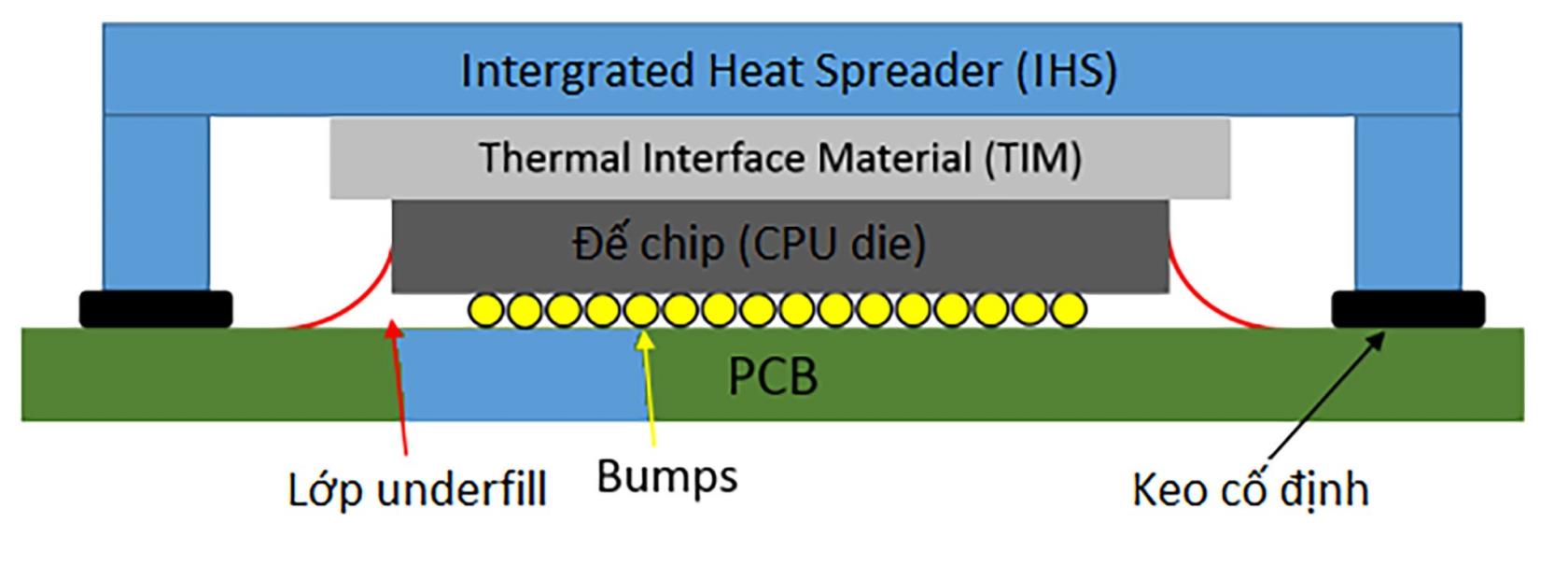

Thermal glue is added in the middle of the heat-emitting surface, here is the CPU cover , GPU base or heat-absorbing surface of the heatsink. The reason there must be thermal paste is because it plays the role of filling up the very small defects on the contact surface of the two metal surfaces being applied.

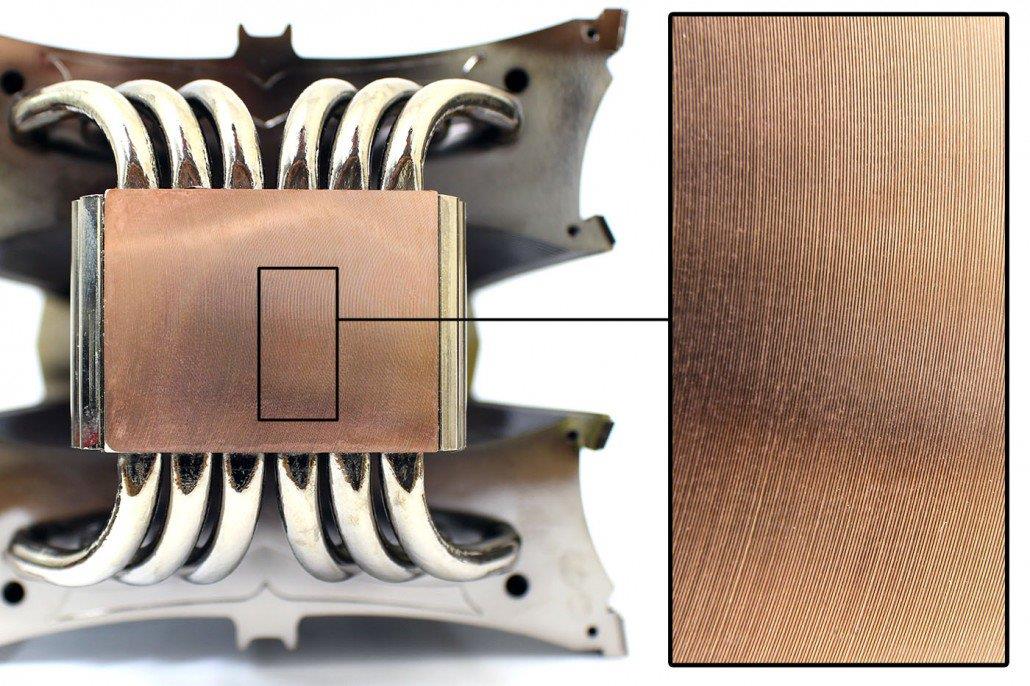

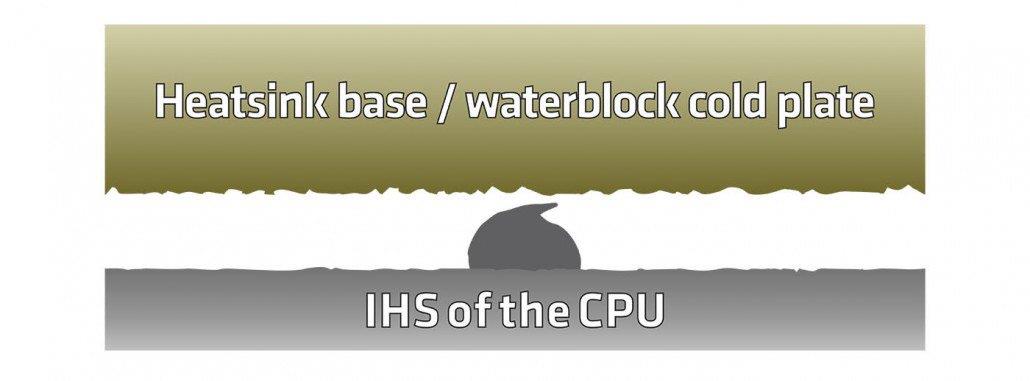

Each CPU or GPU has a surface to diffuse heat from the bottom semiconductor substrate. With CPU, this cover is called IHS (Integrated Heat Spreader), it transfers heat from the chip base up and between the chip base and the IHS cap there is also a TIM layer. The IHS cap will be in direct contact with the heat absorbing surface of the air cooler or the block of the water cooler. The problem is that these two metal surfaces are never perfect, even though they are very flat to the naked eye, in fact there are still tiny holes and grooves that can only be seen under a microscope.

The microscopic space left between the IHS cap and the contact surface of the radiator contains air. Air conducts heat so poorly that thermal paste needs to be added to fill these gaps, creating a "smooth" and sealed heat-conducting surface.

How many types of thermal paste and its quality affect CPU cooling performance?

There are three main types of thermal paste on the market today: metal-based, ceramic, and silicon-based.

Metal-based thermal paste is a glue with very good heat transfer performance. This type of dispersion glue contains tiny metal particles, which can be silver, zinc, aluminum, copper. This glue has a disadvantage that in addition to good thermal conductivity, it can also conduct electricity due to the presence of metal. However, today, many companies have improved with the conductive isolation layers and structures in the glue. This is also the type of glue that you can easily find on the market.

Ceramic glue usually contains ceramic particles, ceramic conducts heat very well and this is also a very safe glue. Of course, ceramic glue does not achieve the same good heat transfer performance as metal-based glue. The difference in temperature can be from 1 to 3 degrees Celsius.

Silicone-based adhesives usually contain silicon and zinc. This glue usually comes with the CPU's stock heatsink and its cooling efficiency is usually average.

There are also liquid metals with excellent heat conduction efficiency. It has the main ingredient Gallium - a soft metal that melts at a temperature higher than normal (29 degrees Celsius), is not as toxic as mercury, and when combined with Indium and other metals, the temperature The melting and freezing of this alloy falls to - 19 degrees Celsius. This means that at room temperature, the liquid metal is always in a liquid state. This glue, in addition to its excellent thermal conductivity, also has high electrical conductivity, so be careful when using it. In addition, it has corrosive properties to aluminum, so liquid metal is often used by users when opening the IHS (delid) CPU cover to apply directly to the semiconductor base.

Going back to the first question, if you find that the device is too hot when playing games or just running common tasks, it is highly likely that the machine has been used for a long time and the thermal paste has dried up, the ability to conduct heat is not good. It's still good and what you need to do is remove the machine to re-apply new glue as well as clean the cooling fan.

About liquid metal:

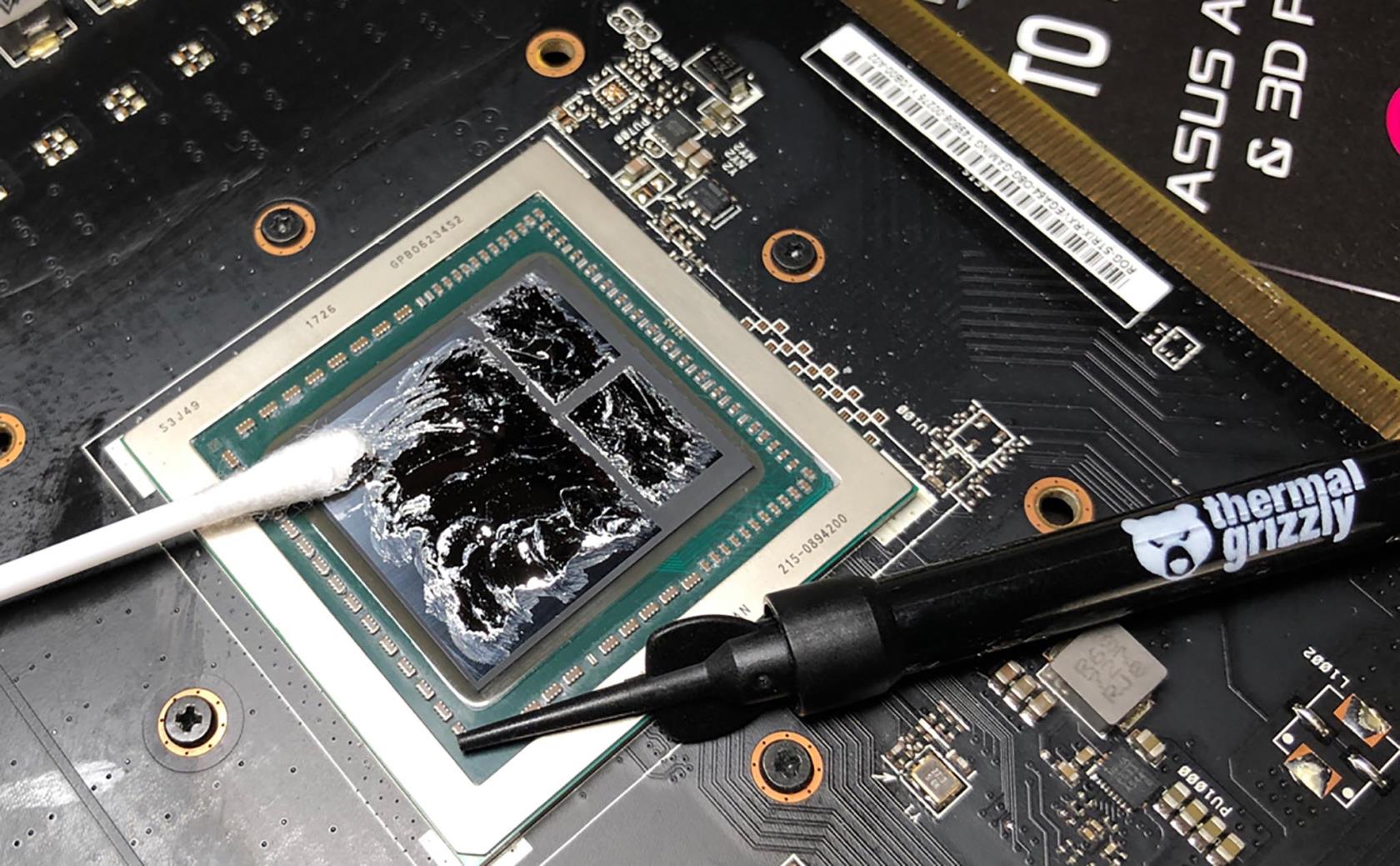

Liquid metal glue has a flowing property, it does not harden under heat like ceramic glues. So during use, metal glue can leak around and if it sticks to other components, it can cause a fire by conductive metal glue. So to apply liquid metal glue, we should use a cotton swab and apply it evenly on the contact surface of the CPU.

Then, you need to create a layer to isolate the CPU's contact area from other components. The usual solution is to use clear nail polish with the main component of polymer to sweep on the surrounding components, when the paint dries it will create a very effective isolation layer with liquid metal glue. Another option is to apply insulating tape.

The type of glue I still use is a common dissipative glue like metal glue, ceramic glue, easy to buy and safe. However, care should be taken not to apply too much glue. Usually just a small lump in the middle of the CPU cover, when you apply the heat sink and tighten the screw, the pressure will cause the glue to spread to fill the gaps as well as the entire contact surface.

And that's a summary of thermal paste as well as notes related to applying thermal paste, if you want more information, continue to follow WebTech360's news, we will continue . Bringing you information, interesting.

Source: Tinhte.vn

Discover how many MB is 1GB and understand the data consumption for various activities to optimize your internet usage.

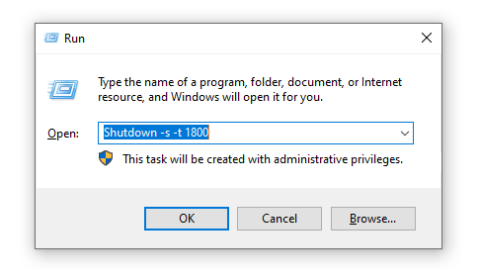

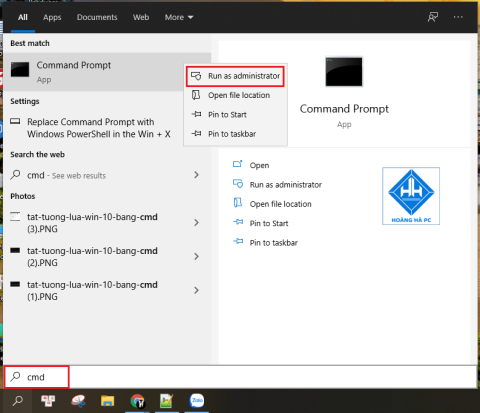

Have you ever set the time in your computer? WebTech360 will introduce you to the most effective and easiest ways to schedule shutdown in Windows 10.

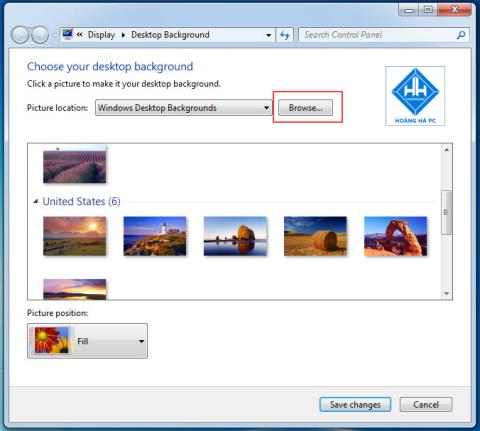

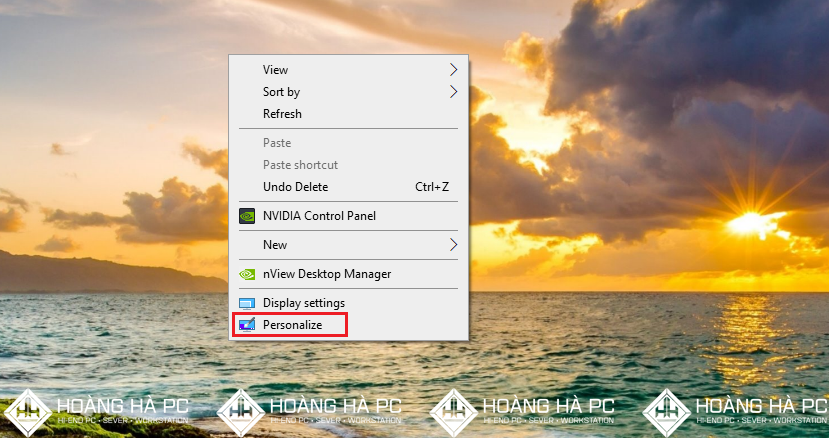

Computer wallpaper is boring, want to find a more aesthetic and beautiful computer image. WebTech360 will show you how to set your desktop wallpaper for Windows 7 and 10!

How to find the IP address and change the computer IP? Join WebTech360 to learn about IP addresses and very simple ways to change computer IPs.

How to adjust screen brightness Win 7 makes it easier for you to adjust the brightness according to your wishes. Let's find out with WebTech360 now!

Windows 10 is the most developed operating system with nearly 10 versions. Which version of Windows 10 should be installed is light and best for the computer and suitable for the job.

Sleep mode is a useful tool for those who have to regularly use the computer. Let's refer to the simple ways to turn off Sleep mode in Windows 10 below!

With the problem that the computer does not turn off during use, WebTech360 will guide you through simple ways to handle the error.

The operating system failed to find the computer in the LAN. WebTech360 shares how to fix Win 10 operating system that cannot connect to LAN.

Clock runs fast or slow wrong time on the computer. WebTech360 shares the reason why the clock in the computer is running wrong and the simplest way to fix it.

WebTech360 introduces computer power consumption measurement software to help calculate the effective and accurate power consumption that you can refer to.

WebTech360 - Share your perfect desktop wallpaper. Our wallpapers come in all sizes, shapes and colors, and they're all free to download.

Step-by-step guide on how to create a green tick for Facebook. Learn how to verify your account and gain credibility with the green verification mark.

Learn how to download torrent files directly using the Firefox web browser with the Torrent Tornado add-on. Simple steps for effective torrent downloading.

Learn how to view someone else’s TikTok followers, both on public and private accounts. Discover effective methods to access follower counts and improve your TikTok strategy.

Learn how to login to Facebook using your email, phone number, or even QR Code authentication without entering a password.

Learn how to stop echo during your Parsec streaming sessions with effective solutions. Echo is a common issue that disrupts communication in games, and we provide proven methods to eliminate it.

Discover how to change your avatar and cover photo on Zalo to express your personality. Follow our easy guide and optimize your Zalo profile image.

Learn how to manage your relationships on Zalo by marking close friends, similar to Instagram. This feature allows easy access to frequently contacted individuals.

Learn how to send screenshots via Viber quickly and without saving them. This guide provides step-by-step instructions to enhance your messaging experience.

Learn how to easily restore deleted messages on Zalo with our step-by-step instructions. Quickly recover your important chats on this popular messaging app.

Discover how to easily add background music to your personal Zalo page with our comprehensive guide on using Zalo for Android and iOS devices.

If you’ve ever found yourself at the end of a Minecraft raid, searching for the last raider to eliminate, you’re not alone. Many players have faced this challenge.

Learn how to uninstall Coc Coc browser completely from your computer, ensuring all data is removed. Follow these simple steps for an effective uninstallation.

Discover how to effectively use the Toshiba AW-A800SV washing machine control panel with our detailed guide!

Discover how to effectively use emergency features on Samsung Galaxy Watch and other smartwatches, including SOS alerts, fall detection, and health records.

Discover how to effectively <strong>share QR code on Zalo</strong>. QR codes enhance connectivity, enabling easy friend requests and more on Zalo.