It is known that the quality of a structured cabling system directly depends on the quality of the cables themselves, passive and active automotive equipment, and the level of training and responsibility of the installation team. The role of the battery-operated crimping tool plays an important role in the efficient operation of the system. A vintage crimper has always been the element that is almost invisible to most users, but it’s the one that determines the performance of the line. A good quality cable crimping tool is one of the most important factors for a successful cable network.

Working with a cable almost always begins with stripping it from external insulation. This operation can be performed with a special tool called a stripper, or you can buy a crimping tool of a more universal type. Among telecommunication installers, the most common and vital tool is a twisted pair crimping tool. Crimper tools are often versatile tools that combine tools of various types and purposes. You can buy all the wire crimping tools wirefyshop.com/collections/wire-crimping-tools at Wirefyshop. There is a wide selection of wire crimpers and other tools for different types of work.

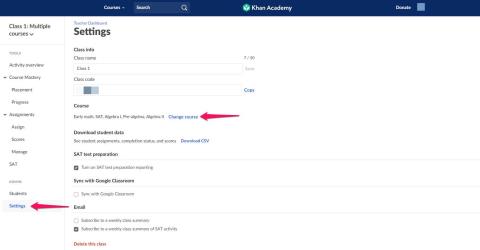

Step-by-Step Guidelines on How to Use a Crimper

Crimping is a method of connecting a wire and a contact and a wire. Through it, a continuous one-piece connection is formed between the cable and the connecting element. The reliability and safety of such an electrical connection can only be guaranteed by using high-quality precision instruments. In the process of crimping a barbed wire, you’ll need not only a wire and a connector, but also a stripper (a device for stripping the insulation), a crimper, and a tool for terminating the cable. When you choose a crimper on Wirefy, perform the following steps to use it the right way:

-

Using a cutter, trim the end of the wire rope ferrule/ferrules or remove the layer of insulation that interferes with crimping.

-

Install the crimp section that matches your terminal type in the crimper seat - with or without insulation.

-

Place the wire in the short steel cylinder in the insert.

-

Use the handles to squeeze the sections in which the terminal lugs are located (for devices that develop small crimping forces, this procedure will have to be repeated several times).

-

Release the handles. The return spring will do the rest.

If the crimper for crimping the automotive terminals did not disappoint you, then the connection will be of high quality, and there will be no current loss at the assembly site. Pay attention to the models for which knives, nippers, pliers, and a set of up to 5 interchangeable attachments designed to work with spark plug wires of different diameters are included.

An important parameter is a crimping force: if it isn’t sufficient, then the crimper will have to be used several times in a row to crimp a strand wire, which is tiring. The lack of a mechanism for adjusting the crimping force significantly limits the demand for tooling. Too little crimp will result in poor mechanical properties and poor electrical conductivity of the joint. If you want to get a top-quality stainless tool, check the sets offered at a Wirefy store where everyone will find toolsets for his/her budget.